Steps towards a sustainable future in the garment sector – the story of PIRIN-TEX

Let me introduce you to one of the most successful companies in garment sector in Bulgaria – PIRIN-TEX – and our steps towards a more sustainable future as an example of what an SME can do to improve its environmental footprint. Below we look at our history and our four main steps towards sustainability.

The Pirin-Tex factory

The company started as a small home tailoring workshop of the Rollmann family in Germany, 1922. Since 1993 the company moved to Gotse Delche, Bulgaria. Thanks to hard work, entrepreneurship, and an unrelenting desire for improvement, today the company is one of the largest clothing producers in Europe. Thanks to the trust, loyalty and cooperation of our employees, clients and partners, we manage to continuously enhance the scope of our operations. Therefore, we invest each year in the modernisation of our technologies and in the improvement of our work environment. Our objective is to continuously develop our production and keep pace with the newest requirements of the international markets, while at the same time reducing the carbon footprint of our activities.

The care for the environment and the protection of nature are our everyday tasks. Led by this conviction, the company has made significant investments in different sustainability projects over the years. We have ambitious goals that are embedded in our everyday work:

- to be garment producer №1 in Europe

- to be one of the drivers of innovations and technological progress in our sector

- to turn Industry 4.0 into reality in our production

- to provide good labour conditions and long-term perspectives for our young specialists

- to protect the nature, our employees and our clients from any harmful impacts resulting from our activities

How do we at PIRIN-TEX meet these goals and how can other companies in the garment sector seek a successful but also sustainable future?

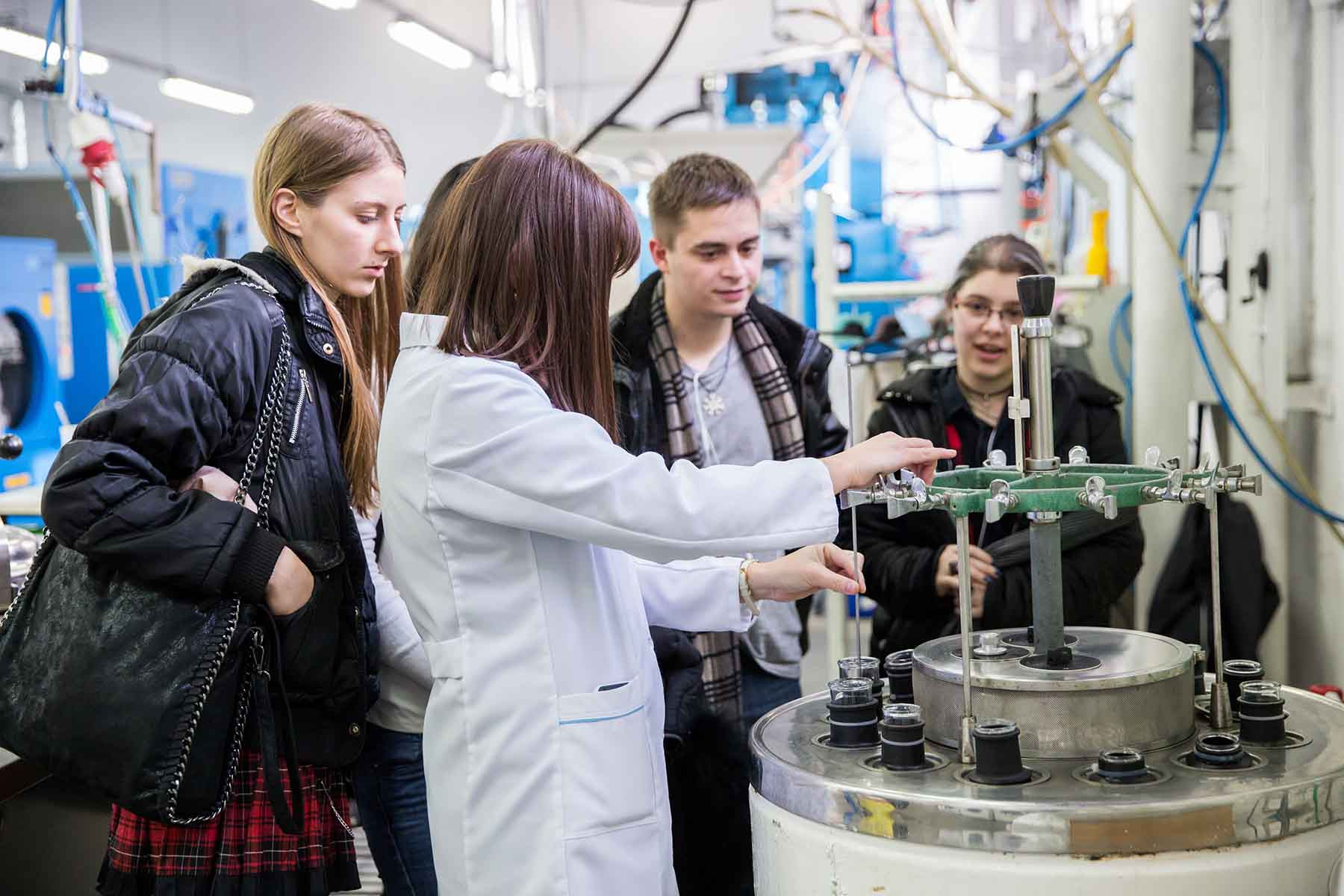

Industry 4.0 in progress

First, recycling. We truly believe that it’s our duty to do minimise our activities’ impact on the planet Setting up an internal department for recycling is a best practice to apply. We gather, sort and bale over 95% of our textile, paper and plastic waste, and sell it as raw materials for the recycling industry.

Second, we consider waste water. In our own treatment plant, the waste water from our washing and dyeing department is purified mechanically, chemically and biologically and undergoes constant control against residues. Every day at over 100 measuring points in the factory, the consumption of electricity, gas, water, steam and compressed air is documented. Thus, changes in consumption and possible sources of loss can be identified and immediate maintenance or repair measure can be initiated.

Third is energy. In 2020 the first photovoltaic power plants installed and enlarged over the subsequent years. Our photovoltaic system covers about half of our electricity consumption and saves 1 470 tons of carbon dioxide per year. This corresponds to 37,565 newly planted trees. Very soon we will also be able to boast about 3 energy storage batteries. All of this is part of the long-term investment strategy of the company and the implementation of our policy for greater sustainability on the way to a green economy.

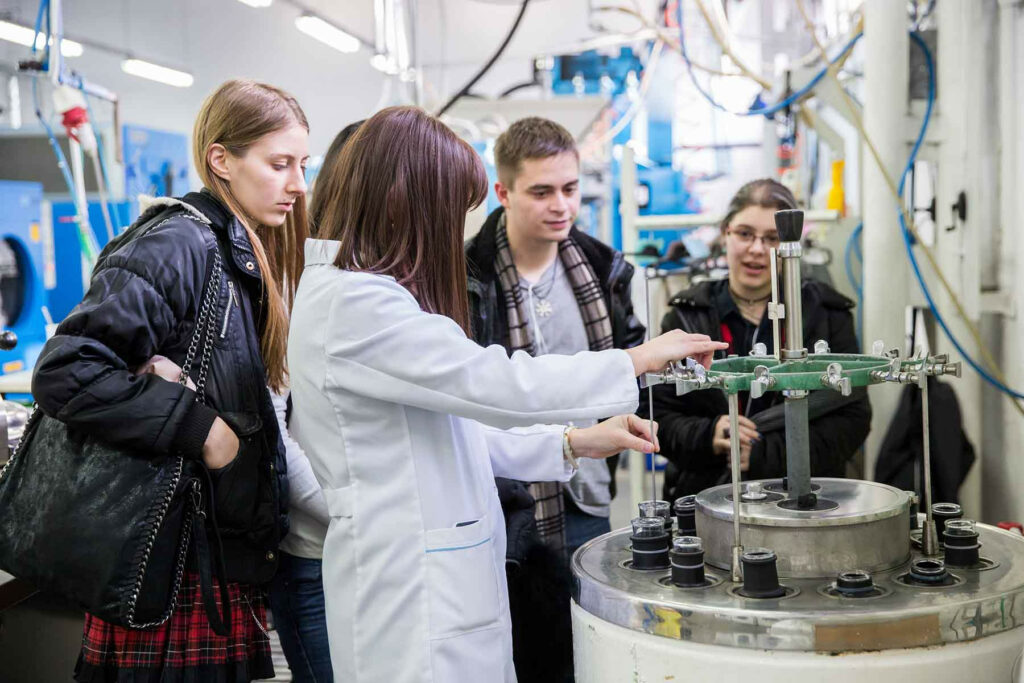

Investing in education

Last but not least, people are of enormous importance of the successful and sustainable development of a company. That’s why we invest in ensuring that they are trained and qualified. We organize training courses for our staff and various internship programs for future sustainable textile workers, that serve as a good bridge between the real working environment and learning. A very good option for this is the Green Vetrine course, which can be used by SMEs to align their staff to sustainability goals.